Posted on October 10, 2018

Pontoons get heavy from the waves, which by their nature are characterized by 4 parameters :

Height – Period – Direction and length of the wave.

The fourth and most fundamental parameter is the “wave length” which in addition to depending on the first 3, also depends on the depth of the seabed.

All the energy of the wave motion breaks on the walls of the pontoons.

For this reason, they must be produced with a high mechanical stability.

The dredging pipe must able to work by acting in all the points of the structure and all the points of the structure must respond to the stresses.

KIASMA HDPE PONTOONS can be used for :

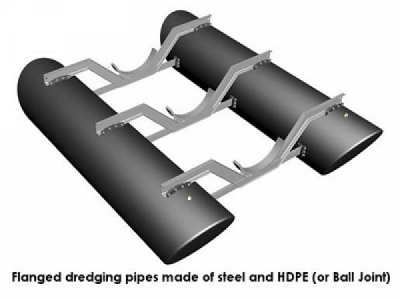

Steel – HDPE – rubber hose pipe lines lenght

5,80 – 11,80 ml with a range from

DN 400mm (16”) to 1000mm (40”)

Out of water pipes (with ball joint)

or semi-submerged (flanged)

Mining pumps installation

(electrical and hydraulic)

It is able to bear weight from 4,35 tons to 17,00 tons for 5,80 ml steel dredging pipe single pontoon, in partiular :

11,80 ml steel pipes – with ball joint – with rubber weight ( n° 2 pontoons)

ID Steel Pipe – Tons

400 mm – 8.80

700 mm – 23.20

800 mm – 34.20

1000 mm flanged – 35.20

TECNICAL DATA – IMPACT FORCE

– Safety coefficient = 1.3

– Density mixture 2.2 t/m3

– Dragging frontal force at 6 Kn speed and Tp. (S) = 3-4

– Lateral force = Wave force with Tp. (S) = 3-4

– High resistance to wave up to 1.5 m. height for single pontoon (evaluated risk for frontal

and lateral waves overturning)

– The buoyancy is guaranteed by plugged and break – wave HDPE pipes (2 or 4 pipes)

5 m. length, OD 630 – 1000 – 1200 made with three watertight parts

11,80 ml steel pipes – with ball joint – with rubber weight ( n° 2 pontoons)

ID Steel Pipe – Tons

400 mm – 8.80

700 mm – 23.20

800 mm – 34.20

1000 mm flanged – 35.20