Posted on July 1, 2024

Research, development and innovation play a vital role in creating new ship designs as well as improving existing vessels. This evolution of ship design is the result of intense cooperation with multiple stakeholders: a company’s own design, engineering and RD&I teams, equipment suppliers, collaborating research institutes and clients.

When Damen delivered its first Service Operations Vessel (SOV) in September 2017, the 90-metre ship was rightly heralded as an example of cutting-edge design. After all, Damen had spent a considerable amount of time collaborating with its client Bibby Marine to create a truly tailor-made solution to carry out operations and maintenance activities for offshore wind operators. That first SOV ticked all the boxes of seakeeping, fuel efficiency, comfortable accommodation and safe transfer of personnel.

Nothing, however, stays the same; especially in the rapidly developing offshore wind industry. “The offshore wind market definitely drives innovation rather than follows it,” says Damen Product Manager SOVs Mark Couwenberg. “The market is really pushing towards reducing emissions – aligning with the climate ambitions of offshore wind farm operators – and increasing operability.” So when Damen started looking at improving the design of its first SOV, in addition to listening closely to its clients’ real-world feedback, it called on its in-house RD&I department to help provide the solutions.

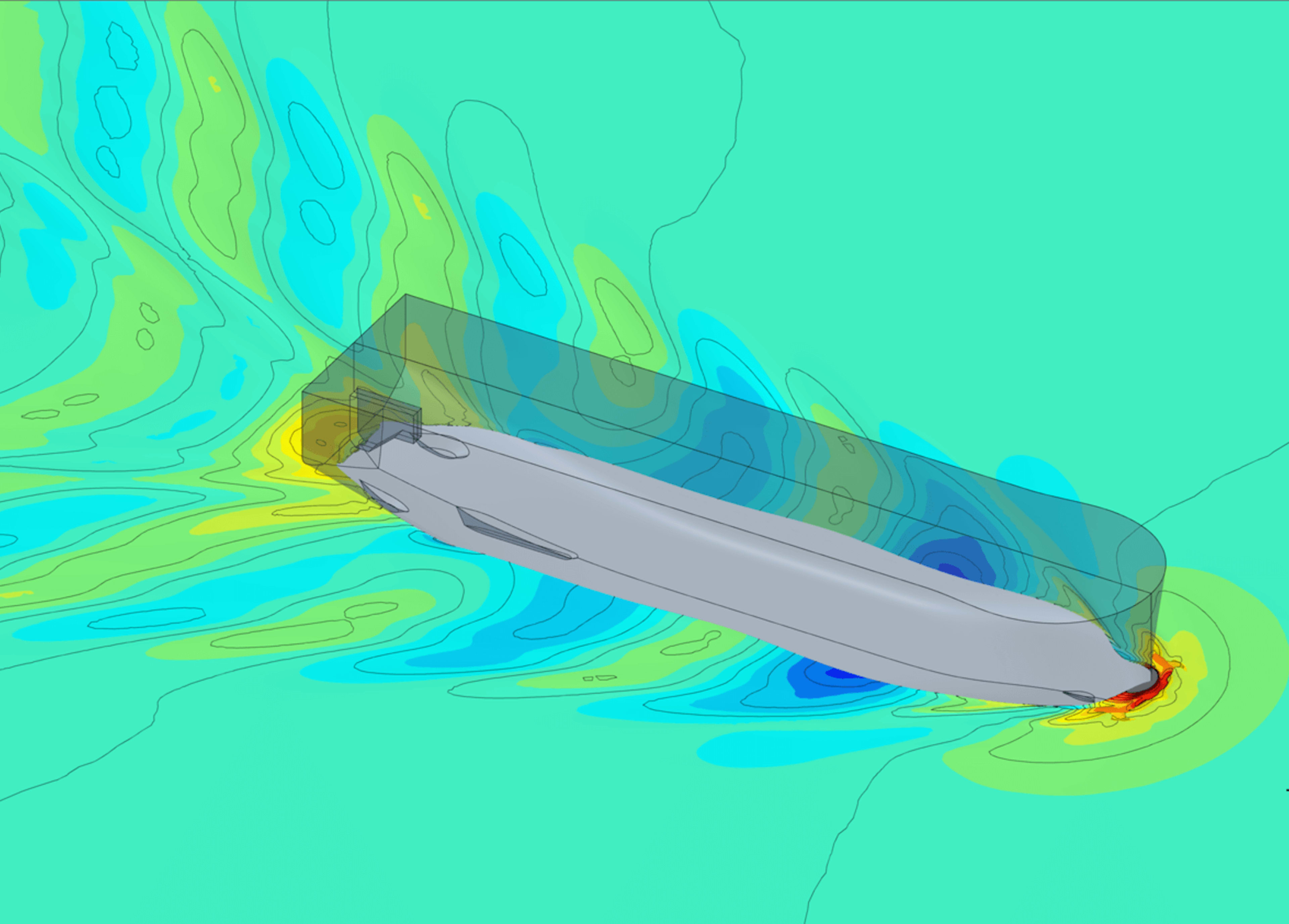

Fast forward to the end of 2022 when Damen announced its design of its second generation SOV (by the way, eight of which are currently under construction for various clients). The company’s RD&I teams had worked on multiple subjects, drawing on knowledge generated from fundamental research within several disciplines. “This included looking at alternative fuels and electrification to achieve CO2 reduction; hydrodynamics to improve the propulsion efficiency, station-keeping and operability; comfort which involves reducing noise and vibrations, and can be extended to onboard logistics,” Couwenberg continues. “Our work into all these subjects can be translated into real life advantages for clients.”

“While we paid a lot of attention to performance and logistics when designing the first generation of vessels, the second generation leans more towards flexibility and optimisation,” says Jorinus Kalis, Damen Development Manager. “For example, the second-generation design has a different thruster layout which promises to improve dynamic positioning performance. Not only will it be quicker to respond, it can perform the same station-keeping duties with less fuel consumption and therefore less emissions. Because we have reduced the basic fuel consumption, this has given us the possibility to add alternative low carbon fuels to the vessels under construction. And in terms of comfort levels, the R&D that we have been doing on this subject has raised the bar.”

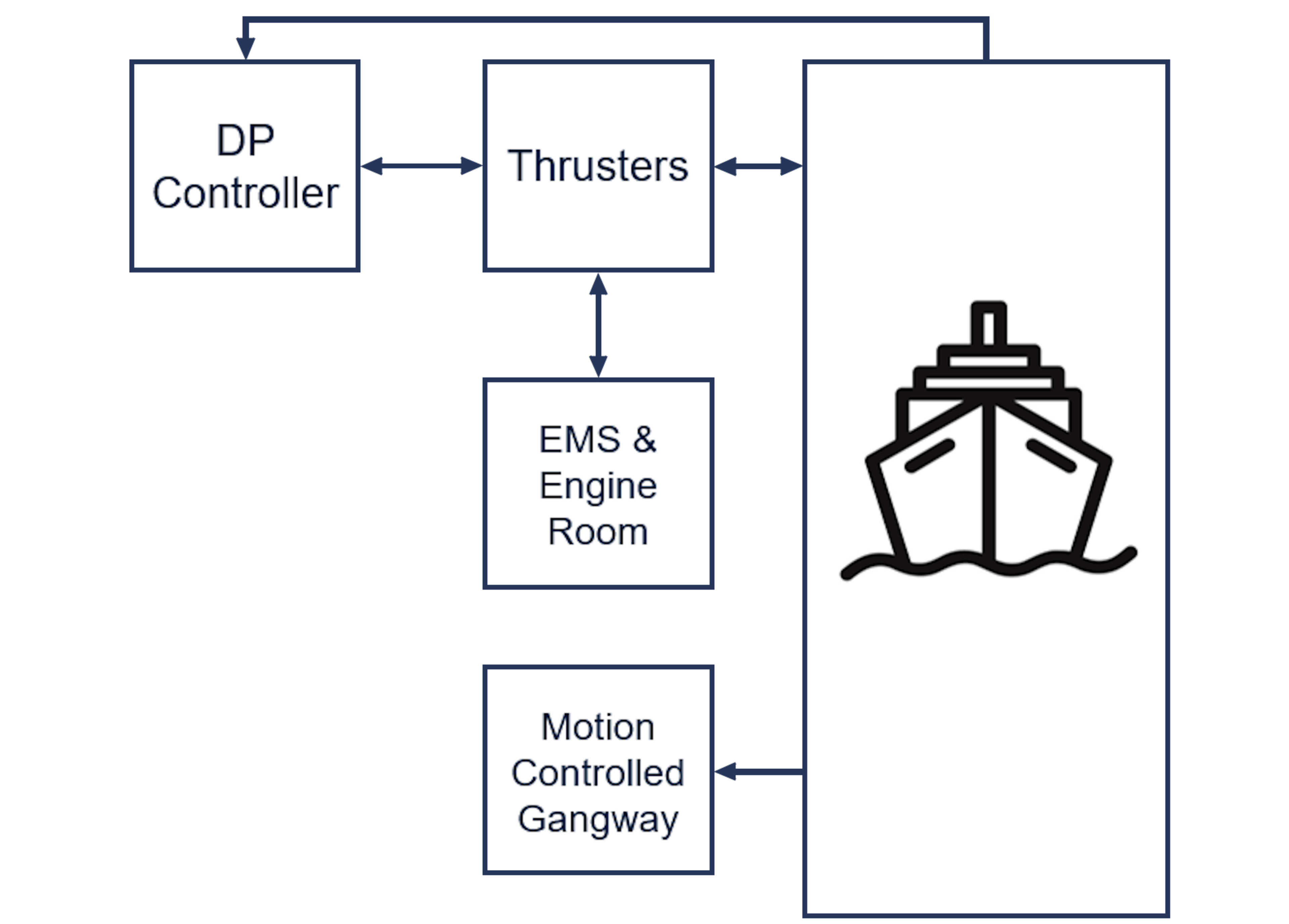

The scope of Damen’s RD&I on its second generation of SOVs also extends into the realm of systems integration. On this point, it is useful to point out that, although Damen made its name as shipbuilder, it is actually more of a systems integrator; delivering ships seamlessly integrated with a fit-for-purpose suite of equipment manufactured by a wide range of suppliers and subcontractors. Accelerating its systems integration abilities significantly, Damen is utilising a secure and collaborative co-simulation environment built by DNV. “Our whole approach to systems integration can now be done in this simulated environment,” says RD&I coordinator for Damen’s CSOV program Karthik Sankaramoorthy. “We work in partnership with our suppliers carrying out the same type of work that previously would have been done during sea trials. Now we can test the integrated performance of all the different systems – power management, DP systems, thrusters, gangways – beforehand, which saves a lot of time and money by providing a solid benchmark of performance settings going into commissioning and sea trials.”

Looking further into the not-too-distant future, Damen released the initial design for its third iteration of the Damen SOV in late 2023. This fully electric SOV-E will be equipped with offshore charging capabilities, thus breaking the ground for some serious emissions reductions. Looking at Damen’s recent history of fully electric vessels, the idea of the SOV-E does not require a huge leap of imagination. “We have delivered the world’s first electric tug, electric waterbuses to Copenhagen, and longer range electric ferries to Canada,” says Couwenberg. “Although there is still a lot of work to be done under the umbrella of emissions reduction, in terms of technology, an electric vessel for the offshore wind sector is a relatively small step.”

In making this SOV-E a reality, the Damen’s RD&I teams will once again be focusing their attention on the key issues. “Besides looking at the availability and storage capacity of greener fuels, this will rely on short charging capabilities. To this end, we are partnering with companies who are working on such solutions, whether it’s working on charging at a substation, turbine or dedicated buoy in the field.” Expected to be hitting the water within the next decade, Damen’s SOV-E will be another demonstration of the cutting-edge results that can be accomplished when the RD&I teams from a shipbuilder and its partners join forces with a common goal.