Posted on September 26, 2018

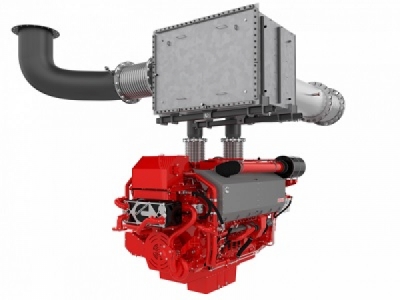

Cummins’ most efficient high-speed engine, designed to challenge medium-speed systems, is now available as part of an equipment package pre-certified to IMO’s Tier III NOx standard.

US engine developer Cummins took the opportunity of the SMM trade fair in Hamburg last month to launch its IMO Tier III certified QSK60 engine package for a wide range of marine applications including commercial workboats.

The QSK60, which features a modular common rail fuel system (MCRS) to ensure accurate high-pressure fuel injection across the engine speed range, was introduced to the marine market in 2008. Cummins has now chosen selective catalytic reduction (SCR) to meet NOx emissions requirements, while focusing on maintaining the engine’s existing fuel consumption characteristics.

Cummins has used SCR with its engines in many markets since 2006, with more than a million such units in the field. In order to reduce the cost impact across the engine’s lifetime, he company aims to optimise diesel exhaust fluid consumption and align aftertreatment maintenance intervals with those of the engine. With eight configurations of engine and SCR available, the company can also offer a wide variety of installation arrangements. This flexibility further contributes to a decreased total cost of ownership

“Cummins engineers have done significant testing of this system to ensure the same dependability, quality and reliability customers have come to expect from our brand,” explains Jim Schacht, executive director, global marine business, Cummins. “With more than 10 years of experience applying SCR to Cummins engines in our on-highway and industrial segments, vessel operators can rest assured they have a great product powering their ship.”

The SCR system is fully serviceable. Catalysts can be removed with standard tools and are expected to match the engine life to overhaul – an example of the principle of aligning engine and aftertreatment maintenance intervals. The vanadia-based catalyst can tolerate fuel with a sulphur content of up to 5,000ppm (0.5%).

SCHEME A CERTIFIED

Cummins offers a pre-certified system using the ‘Scheme A’ approach. This means that Cummins has worked directly with an IMO-recognised agency to perform witness and emissions tests before the system arrives at the shipyard. The design is proven in the test cell to meet the emissions requirements and the various design configurations are all pre-approved.

Since this certification work has been done up front, there are no additional emissions tests required once the construction is complete, removing additional certification complexity from the equation for the shipyard, saving time and money on the total project. The Scheme A approach also ensures the engine and aftertreatment system work together and last over the life of the vessel.

The introduction of the IMO Tier III engine package follows a recent improvement in warranty terms for Cummins marine engines, with an increase in coverage periods. These periods vary depending on the engine family and rating. The base warranty for marine engines 19-60l in a heavy-duty or medium continuous-duty rating has been extended 1,000 hours beyond the previous term, while intermittent-duty coverage for the same engine range has extended 1,500 additional hours.

“The QSK60 now has cleaner emissions and extended” Schacht adds. “The QSK60 is the first Cummins engine platform to receive the IMO III certification but other engines will follow in the near future using similar SCR configurations.”

Source: MotorShip