Posted on October 22, 2018

Caterpillar Marine has detailed a two-pronged approach to urea injection for selective catalytic reduction (SCR), with separate strategies for small and bigger engines.

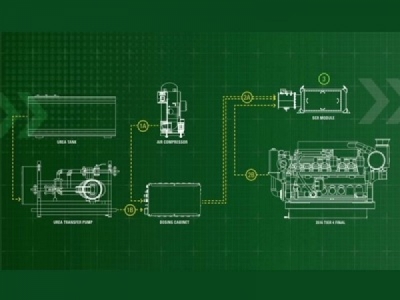

In a new white paper the engine builder explains why its smaller engines – with a displacement of less than 18L (equating to a power output of around 600kW) – will employ airless injection of diesel exhaust fluid, while larger engines in the portfolio (including the MaK range and Cat C280 medium-speed engines) rely on an air-assisted system. According to the company there is a clear cut-off line beyond which using compressed air is more effective than adding multiple injectors.

The company has chosen SCR as its NOx abatement option for marine engines that need to meet EPA Tier 4 and IMO Tier III limits. According to Allen Bowman, product value engineering – marine, oil and gas, Caterpillar, the company chose SCR over its alternative, exhaust gas recirculation (EGR), for several reasons.

“It meets demands for uptime, reliability and durability which are very stringent in the marine sector,” he explains. “SCR allows you to optimise theengine combustion and valve timing strategy in the way that maximises engine efficiency, which reduces fuel consumption. EGR is not exactly new but it is somewhat novel in terms of high-speed marine engine applications.. EGR, and the various complex engine systems it would require to meet Tier 4, elevates the risk to the engine’s reliability and durability.”

Within the field of SCR, there are three elements that distinguish each system – the catalyst, the reductant and the injection method. In the marine sector, the first two are well settled – vanadium is used as a catalyst mainly because it offers good resistance to high sulphur fuels, while urea – also known as diesel exhaust fluid (DEF) – is the fluid of choice. But when it comes to injection, there is a divide between systems that use either airless or air-assisted.

Generally, low- and medium-speed engines use air-assisted injection to dose the exhaust stream with reductant. High-speed engine makers have tended to opt for airless systems. Caterpillar, however, has chosen to adopt air-assisted injection for its larger high-speed engines as well as its medium-speed units.

Bowman explains that the decision was the result of several years of testing and research. The technical justification is detailed in a paper available now in The Motorship website’s new ‘white papers’ section. In brief, air compression allows the manufacturer to minimise the footprint of its SCR units on larger high-speed models, while also ensuring robust mixing and reducing the risk of DEF deposits. And the air compression requirement is not onerous as most vessels using engines of this size will already have a system onboard, although it will require plumbing to the SCR.

Advancing NOx regulations mean the market for such engines is growing. Already EPA Tier 4 requires all ships built in the US to meet emission limits that can only be achieved with NOx abatement. The IMO Tier III legislation is similar, but at present only applies in dedicated NOX Emission Control Areas in North America and the Caribbean. Two further ECAs, in the North Sea and the Baltic Sea, will be enforced from 2021.

The difference between SCR configuration for EPA or IMO regulations lies mainly in the software – IMO Tier III engines will have an option to step down to Tier II NOx performance when not sailing in NOx ECAs, allowing operators to reduce or eliminate DEF dosing to the SCR when only IMO Tier II emissions are required.

Caterpillar has completed its EPA Tier 4 marine engine development with SCR and expects that the majority of its IMO Tier III line up will be completed next year.

Source: The Motorship